LTL Shipping: What is it, and how to save

What is ltl?

LTL, or Less Than Truckload shipping, is a freight transportation method tailored for shipments that are too large to be sent as parcel but not big enough to fill an entire truckload. This makes LTL a cost-effective solution for small to medium-sized businesses that need to transport goods across long distances without bearing the cost of an entire truck.

LTL carriers combine shipments from multiple shippers into one truck. This shared-space approach is not only economical but also environmentally friendly, reducing the carbon footprint associated with shipping goods. When you choose LTL shipping, you’re billed only for the portion of the trailer your goods occupy, while the rest of the space is filled by other companies’ goods heading in the same direction.

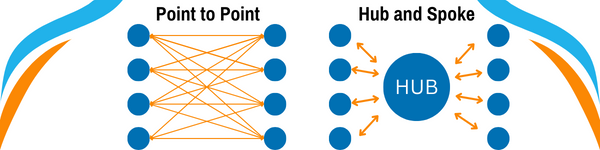

The Hub and Spoke Model

The Hub and Spoke Model streamlines shipments from various shippers to local terminals for sorting and consolidation. These shipments are then efficiently transported to central hubs for reorganization and dispatch to delivery points, optimizing cost and delivery times for LTL carriers.

Advantages of the Hub and Spoke Model:

- Cost Efficiency: The consolidation of shipments allows for fuller loads, which maximizes the utilization of the transportation network and reduces costs per unit.

- Reduced Emissions: By optimizing routes and reducing the number of trips required for delivery, the model helps lower overall carbon emissions, aligning with greener logistics practices.

- Better Traceability: Central hubs serve as control points for monitoring and managing the flow of goods, enhancing the traceability of shipments throughout the supply chain.

Challenges of the Hub and Spoke Model:

- Probability of Damages: With multiple handling points (hubs) where goods are transferred between trucks, there is a higher risk of goods being damaged during transit.

- Potential Delays: The dependence on hub centers means that any delays, such as traffic or operational setbacks at the hub, can affect the timing of deliveries across the network.

- Complexity in Routing: Managing the logistics within hubs to ensure efficient sorting and forwarding can be complex and requires sophisticated systems and processes to handle effectively.

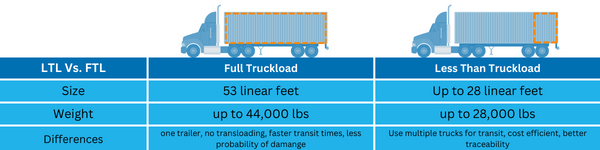

LTL Vs. FTL

FTL is best suited for large shipments that can fill an entire truck, offering the advantage of a dedicated truck for a single shipment which generally results in faster delivery times and less handling risk. On the other hand, LTL is ideal for smaller shipments that do not require the space of an entire truck, allowing multiple shippers to share truck space and costs. While LTL is more cost-effective for small to medium-sized shipments, it may involve longer transit times and increased handling due to multiple stops and transfers. Each method has its own set of benefits, making them suitable for different types of shipping requirements and business needs.

Choosing the right ltl mode

- Standard: A cost-effective option for shipping smaller loads without stringent delivery time requirements. Opt for this mode if you’re looking for the most cost-efficient solution and your shipment is flexible in terms of delivery timeframes, as standard LTL can take longer than other options.

- Expedited: A premium service for urgent LTL shipments that require faster delivery times. This is the go-to choice when time is of the essence. Select expedited service for shipments that need to reach their destination quickly due to tight deadlines or urgent requirements.

- Reefer: Specialized LTL shipping for goods that need temperature control during transit. Use this mode for perishable goods or items that require a controlled temperature environment throughout transit to maintain quality and comply with safety standards.

- Guaranteed: This service offers a guaranteed delivery window for time-sensitive LTL shipments. When your shipment must arrive within a specific window to avoid disruptions in supply chain or production, the guaranteed service ensures your freight arrives on time.

- Volume: Designed for LTL shipments that are larger than typical LTL but do not require a full truckload, often offering cost savings. If your shipment is larger than a standard LTL but still doesn’t require a full truckload, volume LTL can offer a middle ground that balances cost-effectiveness with space requirements.

Additional LTL Services

- Appointment: This service involves scheduling a specific time for pickup or delivery, ensuring that shipments are transported during a window that suits the customer’s needs.

- Lift Gate: For locations without a loading dock, a lift gate service is provided, where a mechanical device is used to raise and lower goods from the ground to the truck.

- Inside Delivery: The carrier delivers items directly inside the threshold of the destination address, rather than leaving them outside or at a dock.

- Pallet Jack: When goods need to be moved within a pickup or delivery location, a pallet jack service is used for easy and efficient handling of palletized cargo.

- After-hours/Before-hours: This service accommodates pickup or delivery outside the standard business hours, ensuring flexibility for businesses with non-traditional operation times.

- Redelivery: If a delivery attempt is unsuccessful, the redelivery service ensures the carrier will return to the destination to try delivering the goods again.

- Limited Access: For deliveries to locations with restrictions or constraints that limit accessibility, this service addresses the extra efforts required.

- Residential: Tailored for deliveries to non-commercial, residential areas, this service often involves smaller vehicles and additional handling.

- Advanced Ship Notice: A pre-alert that is sent to notify a receiver of the details of a shipment before its arrival, allowing for better preparation and handling.

- Freezing Protection: Goods susceptible to cold are protected against freezing temperatures during transit, maintaining the integrity of the freight.

- Sorting/Segregating: This service is used when goods need to be sorted or segregated according to certain criteria during loading or unloading, which requires additional handling and organization.

- Blind Shipment: The shipping process is conducted without revealing the identity of the shipper or receiver to the other party, often used for privacy or trade protection.

- Lumper: Refers to third-party services that are hired to load or unload the cargo from the vehicle, which is common in warehouses or when special handling is required.

- Exhibition: Specialized shipping services for trade shows or exhibitions that may include setup, dismantling, and careful handling of display materials.

Factors influencing ltl rates

- Weight: Heavier shipments generally cost less per hundred pounds

- Density: Calculated by dividing the total weight (including pallets and packaging) by the total cubic feet.

- Classification of Freight: Determined by the National Motor Freight Classification (NMFC), required for all shipments.

- Accessorial/Surcharges: Includes additional services like lift gate service, residential delivery, and fuel surcharges, with some charges potentially being negotiable or waivable.

- Distance: Longer hauls typically incur higher costs per hundred weights, especially when shipments are transferred between carriers (interlining) outside the primary carrier’s service area.

Common Extra charges on your LTL Shipments

- BOL Correction Fee: A charge applied when the Bill of Lading (BOL) must be revised due to inaccurate information.

- Reconsignment: A fee for changing the delivery destination while the shipment is in transit.

- Loading/Unloading: Charges for the service of loading and unloading freight from the transportation vehicle.

- Oversized or Overlength: Additional fees for cargo that exceeds standard dimensions.

- Storage: Costs incurred when freight needs to be stored at a facility during transit.

- Reclassification and Reweigh: Fees applied if the freight class or weight is different from the listed on the BOL.

- Layover: Charges that apply when a driver is forced to wait overnight or for an extended period before delivery can be completed.

- Missed Pick Up Attempt: A fee charged when the carrier attempts to pick up a shipment but is unable to do so due to shipper error.

- Detention: A detention fee is charged when a truck is held beyond a specified loading or unloading time, resulting in delays for the carrier.

How to Save on your LTL Shipments

Pool Consolidation and Distribution:

“Pool consolidation” is the start of the journey, while “pool distribution” is the end where shipments are unloaded, organized, and sent to their destination.

This allows you to consolidate shipments to multiple destinations in the same region, using full trailers for most of the journey. It offers significant savings, reduces shipping times, and keeps products safer by minimizing handling.

Accurate Measurements in the BOL:

This provides both the driver and carrier with all the necessary information to accurately prepare and document the cargo. Accurate weight and size are crucial for determining shipping costs and avoiding potential damage. Be precise to optimize space and prevent costly mistakes.

Proper Packaging:

To decrease the risk of damage during shipments, you will want to ensure you are using the right packaging on your cargo. From bumps in the road to rough handling, your freight will be put through scenarios that are prime for damage. Before you decide and start buying materials for your shipments, head over to the NMFC site to read about the specifications, rules, and requirements you’ll need to check off.

Inner Packaging:

- Bubble wrap

- Foam cushioning

- Honey comb

- Loose-fill

- Paper pads

If your item will be moving around: Use loose-fill, polystyrene, or custom foam packaging to help keep stable and avoid constant bumping.

If your cargo is fragile: Bubble wrap is a light, cheap, and versatile option to help cushion. Egg crate foam is a more expensive option but an even better insulator against hard impact during transit.

Are you using the material more than once? Look for packaging like polyethylene foam that is resistant to water, mold, and mildew while also providing cushion from impacts. If you’re not reusing it, polyfoam will work fine for the one-off shipments.

Electronics: Use an anti-static foam to help mitigate electrostatic charges.

Corrosive Products: Corrosive protective packaging will be required.

Outer Packaging:

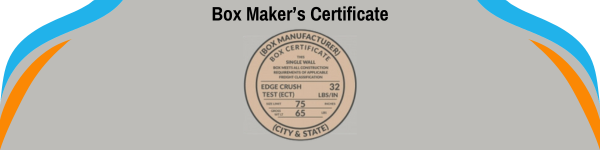

Corrugated fiberboard boxes (CFBs) are the go-to choice for many shippers because of their widespread availability and utility. However, it’s important to note that these boxes aren’t the sturdiest contenders for long-term use or multiple trips, as they tend to lose their strength and integrity over time.

If you’re planning to ship liquids or items that might change state—such as expanding, liquefying, or vaporizing—during transit, the National Motor Freight Classification (NMFC) guidelines are clear: use containers designed to prevent any leakage. This ensures the safety and integrity of not only your product but also the entire shipment on board.

Additionally, for CFBs, Rule 222 specifically details the necessity of a Maker’s Certificate. This certificate provides the maximum specifications for what each box can safely carry. Overloading can invalidate your insurance claims for any damages. So, choose your box wisely and pack thoughtfully to guarantee a smooth delivery process.

What is item 180?

The NMFC rule, Item 180 (also commonly called the “65% rule” outlines that shippers are required to use at least 65% of the pallet or skid’s surface area and at least 65% of a crate or container’s volume. If these conditions are not met, the carrier reserves the right to reclassify the freight based on whether it is loaded on a pallet/skid or within a crate/container.

Labeling your LTL Cargo:

Tags, markings, and labels act as a communication link between shippers and handlers, offering key details for handling packages carefully. Ensure they contain the names, addresses, and zip codes of the shipper and consignee for a clear journey from start to end. To prevent mishandling, place labels on all sides of the package. Utilizing pictorial markings sets the highest standard. These visuals are a universal language for carriers, swiftly conveying handling instructions such as fragility, orientation requirements, or hazardous contents. It’s a visual conversation that outlines the package’s contents and the necessary care at every stage of the process.

How to Palletize your shipments correctly

Rule 680 on palletizing cartons offers valuable tips on stacking and organizing shipments on pallets with care. Following these guidelines allows the boxes to remain sturdy and intact during transport. The column stack method is highly recommended for its efficiency. It’s crucial to avoid practices that may jeopardize the shipment, such as overhanging, misalignment, exposure to high humidity, and creating pyramid-shaped loads. These can weaken a box’s compression strength and potentially lead to issues during transit.

Pro Tip: For LTL shipping, consolidating packages onto a single pallet can be yield savings. By limiting the number of individual items shipped and combining them into fewer units, your carriers will love you and you’ll get a nice boost in efficiency for both parties involved.

Convert your LTL Shipping into Profits

Outbound:

Businesses can choose carriers directly for outbound LTL shipping, billing customers for both product and freight charges. With expertise and carrier relationships adding value, adding a markup can enhance efficiency and profitability, strengthening partnerships. If a business’s expertise in shipping and relationships with carriers add significant value, then adding a markup is justified.

Inbound:

To reduce inbound LTL freight costs, consider switching your shipping terms from “prepaid and add” to “collect.” This approach allows you to eliminate any handling charges by having your vendor or supplier ship using your recommended carrier directly to you, saving you money in the process. By gaining control over inbound shipping, you can streamline truck arrivals, reduce carrier variety, and schedule deliveries strategically. Opting for “Collect” billing means direct invoicing at a discounted rate, avoiding on-the-spot payments.

Conclusion

Mastering LTL shipping can transform it from a logistical challenge into a strategic advantage for your business. Whether you’re sending or receiving goods, understanding, and implementing the best practices for LTL shipping can lead to significant cost savings, improved efficiency, and stronger relationships with carriers. From choosing the right packaging to optimize protection and minimize costs, to selecting the most suitable shipping terms and conditions, every decision counts. Embracing strategies like pooling shipments and optimizing the routing via the “Collect” system allows businesses to exercise greater control over their logistics operations.

Need help boosting your LTL strategy? Feel free to shoot as a call or connect with us here.